IoT Solution Transforming the Way Water Trace Automation (WTA) Monitors the Performance of its Clients’ Operations

Case Study: Network Innovations' FieldIntell IoT Solution Transforming the Way Water Trace Automation Monitors the Performance of its Clients’ Operations

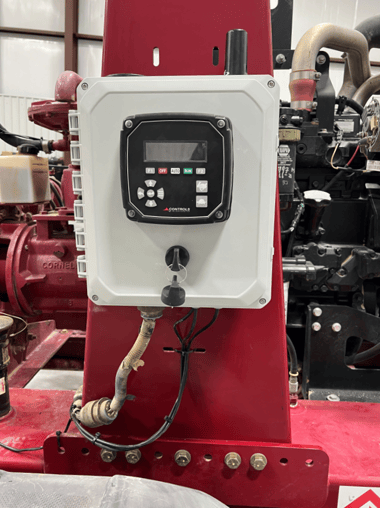

Network Innovations' IoT Solution, featuring FIC-E2000, provides WTA’s clients with full remote visibility into pump health and performance.

The challenge

The challenge

Optimizing water treatment, production, distribution, and consumption is critical in the energy sector; preventing wastage and enhancing the efficiency of operations can make the difference between success and failure in hydraulic fracturing.

Labor and maintenance costs are an expensive overhead in any company. When field pumps are deployed across miles of terrain, operators must inspect the readings and updates of their equipment; a task which can take hours and significant manpower when done physically on site.

Water Trace Automation (WTA), the sister company to Trojan Hose & Pump Rental, is committed to providing seamless water transfer services to the energy sector. In an effort to help its clients proactively maintain and manage their pumps, they looked to challenge the conventional methods of asset management monitoring. WTA started to explore if there was a more efficient way to address their clients’ pain points, maximizing production uptime and freeing their workers’ time for more value-adding tasks.

Automating the water transfer process was the best path forward. To do so, WTA required a sophisticated remote monitoring solution, providing real-time visibility into pump health, status, and performance, from anywhere.

THE SOLUTION

THE SOLUTION

Seeking a solution that could offer simple-to-install devices with complete coverage, Network Innovations’ FieldIntell solution, FIC-E2000, was the ideal fit. Purpose-built for installation on remote industrial assets, this compact edge IoT solution allows WTA to better communicate with their equipment - transitioning between satellite and cellular coverage for resilient and uninterrupted insight.

Seeking a solution that could offer simple-to-install devices with complete coverage, Network Innovations’ FieldIntell solution, FIC-E2000, was the ideal fit. Purpose-built for installation on remote industrial assets, this compact edge IoT solution allows WTA to better communicate with their equipment - transitioning between satellite and cellular coverage for resilient and uninterrupted insight.

With over 300 units deployed across multiple fleets, engineers can now solve issues quickly; measuring engine data, flow levels, tank meters, and more… in real-time. This information enables them to identify the root cause of any problems, take immediate corrective action, and reduce overall maintenance costs.

Viewing data through Network Innovations’ monitoring platform, FI Control, enables users to manage their fleet from one screen. WTA’s clients are able to easily stop, start, or adjust pumps from their phone, tablet, or desktop.

“Without the FIC-E2000, our clients would simply have no visibility into how their pumps are operating, without physically being at the unit. Since implementing this solution, they can read all pump data from the comfort of their workstation.” – Austin Roberts, Automation Director at Water Trace Automation

![]()

Network Innovations’ FIC-E2000 has transformed the way operators can view the performance of their equipment. Leveraging this IoT technology, WTA now offers a personalized value-add service including complete pump monitoring and control capabilities.

Network Innovations’ FIC-E2000 has transformed the way operators can view the performance of their equipment. Leveraging this IoT technology, WTA now offers a personalized value-add service including complete pump monitoring and control capabilities.

WTA’s clients receive automatic updates on the status of their equipment, with the ability to set smart notifications and alerts as required. Paired with FI Control for the clear retrieval of data, the FIC-E2000 devices have proved effective in reducing emergency callouts, downtime, and costs.

Network Innovations continues to support WTA in their smart-water mission to transfer, operate, and Succeed. Anywhere.

Read On

Notify Me

Get notified when we publish new content